Smooth cutting, low vibration, high durability, good reaming quality, can be used to process holes with intermittent surfaces, such as keyway holes, can avoid reamer being stuck and prevent the teeth from chipping. Right-hand reamer is used for processing blind holes, cutting can be discharged along the groove, left-hand reamer axial force pointing to the shank, so that the clamping is secure, the cutting flow to the direction of the surface to be processed, applicable to the processing of through-hole.

Engineering Data

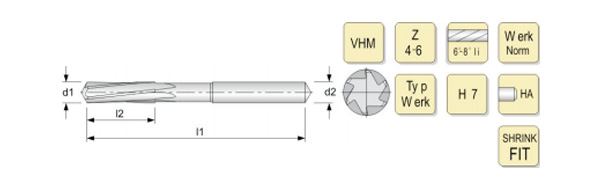

equal division

design as specified acc, DIN 1420

| d1(H7) | d1 | L2 | L1 | z | d2 | d1(H7) | d1 | L2 | L1 | z | d2 | |

| mm | von…bis | mm | mm | (h6)mm | mm | von…bis | mm | mm | (h6)mm | |||

| 2 | 1.90-2.12 | 11 | 49 | 4 | 2 | 6 | 5.81-6.20 | 30 | 93 | 6 | 5.6 | |

| 2.2 | 2.13-2.36 | 12 | 53 | 4 | 2.2 | 6.5 | 6.21-6.70 | 30 | 101 | 6 | 6.3 | |

| 2.5 | 2.37-2.65 | 14 | 57 | 4 | 2.5 | 7 | 6.71-7.50 | 30 | 109 | 6 | 7.1 | |

| 3 | 2.66-3.15 | 20 | 61 | 6 | 3 | 8 | 7.51-8.50 | 32 | 17 | 6 | 8 | |

| 3.5 | 3.16-3.75 | 22 | 70 | 6 | 3.5 | 9 | 8.51-9.50 | 36 | 25 | 6 | 9 | |

| 4 | 3.76-4.25 | 22 | 75 | 6 | 4 | 10 | 9.51-10.50 | 38 | 133 | 6 | 10 | |

| 4.5 | 4.26-4.75 | 22 | 75 | 6 | 4.5 | 11 | 10.51-11.50 | 41 | 142 | 6 | 10 | |

| 5 | 4.76-5.30 | 28 | 86 | 6 | 5 | 12 | 11.51-12.50 | 44 | 151 | 6 | 10 | |

| 5.5 | 5.31-5.80 | 28 | 93 | 6 | 5.6 | 13 | 12.51-13.50 | 44 | 151 | 6 | 10 |

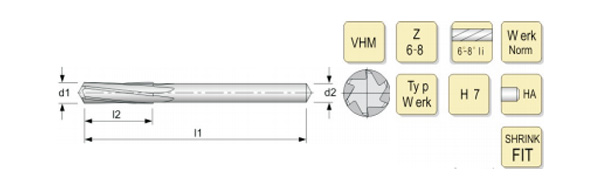

Engineering Data

unequal division

short bevel

design as specified acc, DIN 1420

| d1(H7) | d1 | L2 | L1 | z | d2 | d1(H7) | d1 | L2 | L1 | z | d2 | |

| mm | von…bis | mm | mm | (h6)mm | mm | von…bis | mm | mm | (h6)mm | |||

| 3 | 2.75-3.25 | 16 | 50 | 6 | 2.5 | 7 | 6.76-7.50 | 25 | 71 | 6 | 6.3 | |

| 3.5 | 3.26-3.75 | 16 | 50 | 6 | 3 | 8 | 7.51-8.50 | 25 | 71 | 6 | 6.3 | |

| 4 | 3.76-4.25 | 20 | 56 | 6 | 3.55 | 9 | 3.51-9.50 | 25 | 71 | 6 | 8 | |

| 4.5 | 4.26-4.75 | 22 | 63 | 6 | 4 | 10 | 9.51 -10.5 | 25 | 71 | 6 | 8 | |

| 5 | 4.76-5.25 | 22 | 63 | 6 | 4 | 11 | 0.6-11.5 | 28 | 80 | 6 | 10 | |

| 5.5 | 5.26-5.75 | 22 | 63 | 6 | 5 | 12 | 1.6-12.5 | 28 | 80 | 6 | 10 | |

| 6 | 5.76-6.25 | 22 | 63 | 6 | 5 | 13 | 2.6-13.5 | 28 | 80 | 6 | 10 | |

| 6.5 | 6.26-6.75 | 22 | 63 | 6 | 5 | 14 | 3.6-14.5 | 32 | 90 | 8 | 12.5 |

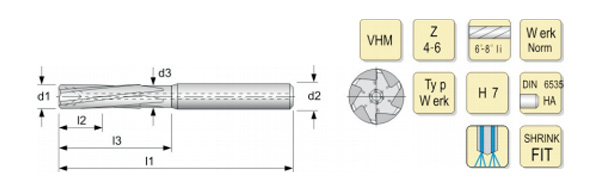

Engineering Data

unequal division

short bevel

LH fluted 6°-8°

design as specified acc, DIN 1420

interior coolant exit in the flutes

| d1 | z | d2 | d1 | z | d2 | |||||||||

| (H7) | d1 | L3 | L2 | L1 | (h6) | (H7) | d1 | L3 | L2 | L1 | (h6) | |||

| mm | von…bis | mm | mm | mm | mm | mm | von…bis | mm | mm | mm | mm | |||

| 4 | 3.97-4.25 | 31 | 10 | 74 | 4 | 6 | 8 | .97-8.25 | 53 | 16 | 93 | 6 | 8 | |

| 4.5 | 4.26-4.96 | 31 | 10 | 74 | 4 | 6 | 8.5 | 8.26-8.96 | 54 | 16 | 93 | 6 | 8 | |

| 5 | 4.97-5.25 | 34 | 12 | 75 | 4 | 6 | 9 | 8.97-9.25 | 60 | 20 | 105 | 6 | 10 | |

| 5.5 | 5.26-5.96 | 34 | 12 | 75 | 4 | 6 | 9.5 | 9.26-9.96 | 60 | 20 | 105 | 6 | 10 | |

| 6 | 5.97-6.25 | 53 | 12 | 93 | 6 | 6 | 10 | 9.97-10.03 | 61 | 20 | 105 | 6 | 10 | |

| 6.5 | 6.26-6.96 | 54 | 12 | 93 | 6 | 6 | 10.5 | 10.04-10.95 | 68 | 20 | 120 | 6 | 12 | |

| 7 | 6.97-7.25 | 52 | 16 | 93 | 6 | 8 | 11 | 10.97-11.96 | 70 | 24 | 120 | 6 | 12 | |

| 7.5 | 7.26-7.96 | 52 | 16 | 93 | 6 | 8 | 12 | 11.97-12.0 | 71 | 24 | 120 | 6 | 12 |

Carbide machine reamer

| Code | Blade Diameter D | Shank Diameter d | Total Length L | Blade count X | Blade length 1 | Grade | ||

| H7 | H8 | H9 | ||||||

| CR40617FH | 6 | 5.6 | 93 | 4 | 17 | +0,012 | +0,018 | +0,030 |

| CR40717FH | 7 | 7 | 109 | 4 | 17 | +0,007 | +0,011 | +0,019 |

| CR40817FH | 8 | 8 | 117 | 4 | 17 | +0,015 | +0,022 | +0,036 |

| CR40917FH | 9 | 9 | 125 | 4 | 17 | +0,009 | +0,014 | +0,023 |

| CR41017FH | 10 | 10 | 133 | 4 | 17 | |||

| CR41117FH | 11 | 10 | 142 | 4 | 17 | |||

| CR41220FH | 12 | 10 | 151 | 4 | 20 | +0,018 | +0,027 | +0,043 |

| CR61420FH | 14 | 12.5 | 160 | 6 | 20 | +0,011 | +0,017 | +0,027 |

| CR61625FH | 16 | 12.5 | 170 | 6 | 25 | |||

| CR61825FH | 18 | 14 | 189 | 6 | 25 | +0,021 | +0,033 | +0,052 |

| CR62025FH | 20 | 16 | 195 | 6 | 25 | +0,013 | +0,021 | +0,033 |

| Code | Blade Diameter D | apertured | Blade length 1 | Total Length L | Blade count X | Grade | ||

| H7 | H8 | H9 | ||||||

| □-CR42532SH | 25 | 13 | 32 | 45 | 4 | +0.017 +0.009 | +0.028 +0.016 | +0.044 +0.025 |

| □-CR63236SH | 32 | 16 | 36 | 50 | 6 | +0.017 +0.009 | +0.028 +0.016 | +0.044 +0.025 |

| □-CR63640SH | 36 | 19 | 40 | 56 | 6 | +0.021 +0.012 | +0.033 +0.019 | +0.052 +0.030 |

| □-CR84545SH | 45 | 22 | 45 | 63 | 8 | +0.021 +0.012 | +0.033 +0.019 | +0.052 +0.030 |

| □-CR85250SH | 52 | 27 | 60 | 71 | 8 | +0.025 +0.014 | +0.039 +0.022 | +0.062 +0.0369 |

| □-CR106356SH | 63 | 32 | 56 | 80 | 10 | +0.025 +0.014 | +0.039 +0.022 | +0.062 +0.0369 |

| □-CR107263SH | 72 | 40 | 63 | 90 | 10 | +0.029 +0.016 | +0.045 +0.026 | +0.073 +0.042 |

| □-CR10857SH | 85 | 50 | 71 | 100 | 10 | +0.029 +0.016 | +0.045 +0.026 | +0.073 +0.042 |