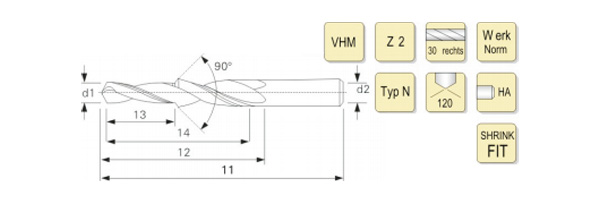

A cost-effective carbide drill with excellent machining performance for a wide range of materials. Very rapid chip removal, four-sided self-centering ensures hole accuracy, optimum cutting edge cross-correction for low drag, stable torque, and fine chip breakage for stable machining.

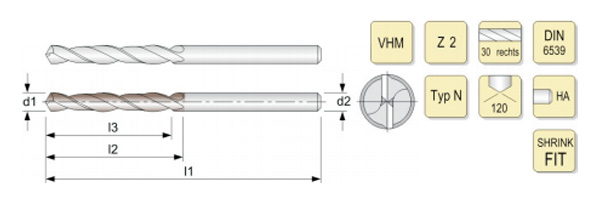

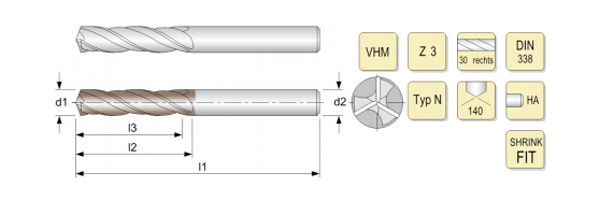

Sodid carbide spiral drill for common machining

Engineering Data

four-sided grinding

left hand cutting

web thinning DIN 1412 form A

30° RH helix

| d1 | d2 | cd1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mn | mm | mm | |

| 3 | 12 | 16 | 46 | 3 | 5.9 | 21 | 28 | 66 | 5.9 | |

| 3.1 | 14 | 18 | 49 | 3.1 | 6 | 21 | 28 | 66 | 6 | |

| 3.2 | 14 | 18 | 49 | 3.2 | 6.1 | 23 | 28 | 70 | 6.1 | |

| 3.3 | 14 | 18 | 49 | 3.3 | 6.2 | 23 | 31 | 70 | 6.2 | |

| 3.4 | 15 | 20 | 52 | 3.4 | 6.3 | 23 | 31 | 70 | 6.3 | |

| 3.5 | 15 | 20 | 52 | 3.5 | 6.4 | 23 | 31 | 70 | 6.4 | |

| 3.6 | 15 | 20 | 52 | 3.6 | 6.5 | 23 | 31 | 70 | 6.5 | |

| 3.7 | 15 | 20 | 52 | 3.7 | 6.8 | 25 | 34 | 70 | 6.8 | |

| 3.8 | 17 | 22 | 55 | 3.8 | 7 | 25 | 34 | 70 | 7 | |

| 3.9 | 17 | 22 | 55 | 3.9 | 7.5 | 25 | 34 | 70 | 7.5 | |

| 4 | 17 | 22 | 55 | 4 | 7.8 | 27 | 37 | 79 | 7.8 | |

| 4.1 | 17 | 22 | 55 | 4.1 | 8 | 27 | 37 | 79 | 8 | |

| 4.2 | 17 | 22 | 55 | 4.2 | 8.5 | 27 | 37 | 79 | 8.5 | |

| 4.3 | 18 | 24 | 58 | 4.3 | 9 | 29 | 40 | 80 | 9 | |

| 4.4 | 18 | 24 | 58 | 4.4 | 9.5 | 29 | 40 | 80 | 9.5 | |

| 4.5 | 18 | 24 | 58 | 4.5 | 10 | 31 | 43 | 89 | 10 | |

| 4.6 | 18 | 24 | 58 | 4.6 | 10.2 | 31 | 43 | 89 | 10.2 | |

| 4.7 | 18 | 24 | 58 | 4.7 | 10.5 | 31 | 43 | 89 | 10.5 | |

| 4.8 | 20 | 26 | 62 | 4.8 | 11 | 33 | 47 | 95 | 11 | |

| 4.9 | 20 | 26 | 62 | 4.9 | 11.5 | 33 | 47 | 95 | 11.5 | |

| 5 | 20 | 26 | 62 | 5 | 12 | 35 | 51 | 102 | 12 | |

| 5.1 | 20 | 26 | 62 | 5.1 | 12.5 | 35 | 51 | 102 | 12.5 | |

| 5.2 | 20 | 26 | 62 | 5.2 | 13 | 35 | 51 | 102 | 13 | |

| 5.3 | 20 | 26 | 62 | 5.3 | 14 | 37 | 54 | 107 | 14 | |

| 5.4 | 21 | 28 | 66 | 5.4 | 15 | 38 | 56 | 107 | 15 | |

| 5.5 | 21 | 28 | 66 | 5.5 | 16 | 38 | 56 | 107 | 16 | |

| 5.6 | 21 | 28 | 66 | 5.6 | 18 | 40 | 58 | 107 | 18 | |

| 5.7 | 21 | 28 | 66 | 5.7 | 20 | 42 | 66 | 131 | 20 | |

| 5.8 | 21 | 28 | 66 | 5.8 |

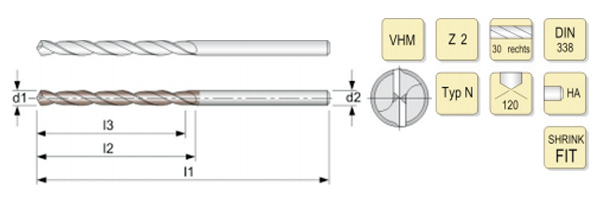

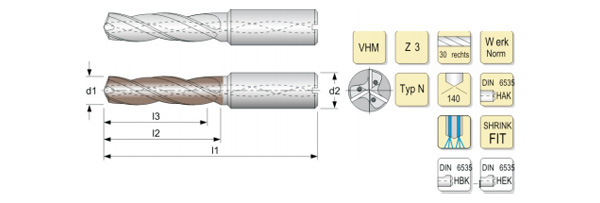

Engineering Data

four-sided grinding

left hand cutting

web thinning DIN 1412 form A

30° RH helix

| d1 | d2 | d1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 29 | 33 | 61 | 3 | 5.6 | 49 | 57 | 93 | 5.6 | |

| 3.1 | 32 | 36 | 65 | 3.1 | 5.7 | 49 | 57 | 93 | 5.7 | |

| 3.2 | 32 | 36 | 65 | 3.2 | 5.8 | 49 | 57 | 93 | 5.8 | |

| 3.3 | 32 | 36 | 65 | 3.3 | 5.9 | 49 | 57 | 93 | 5.9 | |

| 3.4 | 34 | 39 | 70 | 3.4 | 6 | 49 | 57 | 93 | 6 | |

| 3.5 | 34 | 39 | 70 | 3.5 | 6.1 | 55 | 63 | 101 | 6.1 | |

| 3.6 | 34 | 39 | 70 | 3.6 | 6.2 | 55 | 63 | 101 | 6.2 | |

| 3.7 | 34 | 39 | 65 | 3.7 | 6.3 | 55 | 63 | 101 | 6.3 | |

| 3.8 | 37 | 43 | 65 | 3.8 | 6.4 | 55 | 63 | 101 | 6.4 | |

| 3.9 | 37 | 43 | 65 | 3.9 | 6.5 | 55 | 63 | 101 | 6.5 | |

| 4 | 37 | 43 | 75 | 4 | 6.8 | 60 | 69 | 107 | 6.8 | |

| 4.1 | 37 | 43 | 75 | 4.1 | 7 | 60 | 69 | 107 | ||

| 4.2 | 37 | 43 | 75 | 4.2 | 7.5 | 60 | 69 | 107 | 7.5 | |

| 4.3 | 41 | 47 | 80 | 4.3 | 8 | 64 | 75 | 117 | 8 | |

| 4.4 | 41 | 47 | 80 | 4.4 | 8.5 | 64 | 75 | 117 | 8.5 | |

| 4.5 | 41 | 47 | 80 | 4.5 | 9 | 69 | 81 | 125 | ||

| 4.6 | 41 | 47 | 80 | 4.6 | 9.5 | 69 | 81 | 125 | 9.5 | |

| 4.7 | 41 | 47 | 80 | 4.7 | 10 | 74 | 87 | 133 | 10 | |

| 4.8 | 45 | 52 | 86 | 4.8 | 10.2 | 74 | 87 | 133 | 10.2 | |

| 4.9 | 45 | 52 | 86 | 4.9 | 10.5 | 74 | 87 | 133 | 10.5 | |

| 5 | 45 | 52 | 86 | 5 | 11 | 80 | 94 | 142 | 11 | |

| 5.1 | 45 | 52 | 86 | 5.1 | 11.5 | 80 | 94 | 142 | 11.5 | |

| 5.2 | 45 | 52 | 86 | 5.2 | 12 | 85 | 101 | 151 | 12 | |

| 5.3 | 45 | 52 | 86 | 5.3 | 13 | 85 | 101 | 151 | 13 | |

| 5.4 | 49 | 57 | 93 | 5.4 | 14 | 91 | 108 | 160 | 14 | |

| 5.5 | 49 | 57 | 93 | 5.5 | 15 | 96 | 114 | 163 | 15 | |

| 16 | 98 | 116 | 163 | 16 |

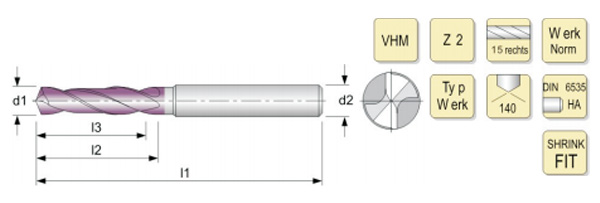

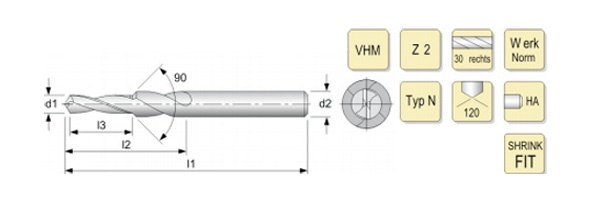

Engineering Data

special point grinding

web thickness reinforced

high abrasion resisstance

15° RH helix

| d1 | d2 | d1 | d2 | |||||||

| (m7) | L3 | L2 | L1 | (h6) | (m7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 9 | 16 | 46 | 3 | 7 | 30 | 45 | 80 | 8 | |

| 3.3 | 9.9 | 18 | 48 | 4 | 7.3 | 30 | 45 | 80 | 8 | |

| 3.5 | 10.5 | 20 | 50 | 4 | 7.5 | 30 | 45 | 80 | 8 | |

| 4 | 12 | 22 | 52 | 4 | 8 | 35 | 50 | 98 | 8 | |

| 4.2 | 15 | 25 | 65 | 6 | 8.5 | 35 | 50 | 98 | 10 | |

| 4.4 | 15 | 28 | 68 | 6 | 8.8 | 42 | 57 | 105 | 10 | |

| 4.5 | 15 | 28 | 68 | 6 | 9 | 42 | 57 | 105 | 10 | |

| 5 | 18 | 32 | 72 | 6 | 9.3 | 42 | 57 | 105 | 10 | |

| 5.3 | 18 | 32 | 72 | 6 | 9.5 | 42 | 57 | 105 | 10 | |

| 5.5 | 18 | 35 | 75 | 6 | 10 | 45 | 63 | 107 | 10 | |

| 6 | 18 | 35 | 75 | 6 | 10.5 | 45 | 63 | 107 | 12 | |

| 6.5 | 25 | 40 | 80 | 6 | 10.8 | 45 | 63 | 107 | 12 | |

| 6.8 | 30 | 45 | 80 | 8 | 11 | 50 | 71 | 119 | 12 | |

| 7 | 30 | 45 | 80 | 8 | 11.5 | 50 | 71 | 119 | 12 | |

| 11.9 | 50 | 71 | 119 | 12 | ||||||

| 12 | 50 | 71 | 119 | 12 |

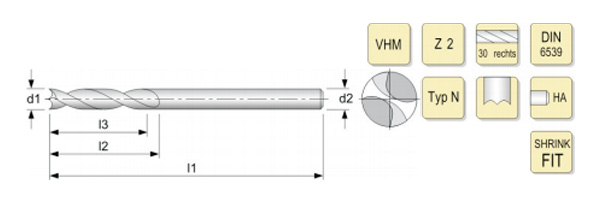

Engineering Data

special point ground for fibre compound materials periphery cutting edge in sickle design

30° RH helix

| d1 | d2 | d1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 12 | 6 | 46 | 3 | 7 | 25 | 34 | 74 | 7 | |

| 3.2 | 14 | 18 | 49 | 3.2 | 7.5 | 25 | 34 | 74 | 7.5 | |

| 3 | 14 | 8 | 49 | 0.3 | 8 | 27 | 37 | 79 | 8 | |

| 35 | 15 | 20 | 52 | 3.5 | 8.5 | 27 | 37 | 79 | 8.5 | |

| 3.7 | 15 | 20 | 52 | 3.7 | 9 | 29 | 40 | 80 | 9 | |

| 4 | 17 | 22 | 55 | 4 | 9.5 | 29 | 40 | 80 | 9.5 | |

| 4.2 | 17 | 22 | 55 | 4.2 | 10 | 31 | 43 | 80 | 10 | |

| 4.5 | 18 | 24 | 58 | 5 | 10.5 | 31 | 13 | 80 | 11 | |

| 4.7 | 18 | 24 | 58 | 4.7 | 11 | 33 | 47 | 95 | 11 | |

| 5 | 20 | 26 | 62 | 5 | 1.5 | 33 | 47 | 95 | 11.5 | |

| 5.3 | 20 | 26 | 62 | 5.3 | 12 | 35 | 51 | 102 | 12 | |

| 5.5 | 21 | 28 | 66 | 5.5 | 13 | 35 | 51 | 102 | 13 | |

| 5.8 | 21 | 28 | 66 | 5.8 | 14 | 37 | 54 | 107 | 14 | |

| 6 | 21 | 28 | 66 | 6 | 15 | 38 | 56 | 7 | 15 | |

| 6.5 | 23 | 31 | 70 | 6.5 | 16 | 38 | 58 | 107 | 16 |

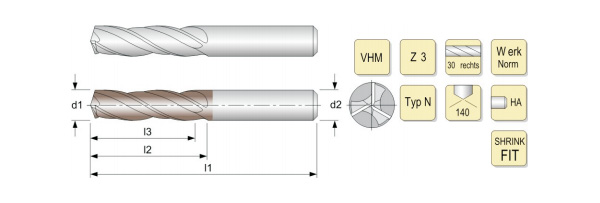

Engineering Data

four-sided grinding

web thinning standard

long design

30° RH helix

| dl | d2 | dl | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 29 | 33 | 61 | 3 | 9.5 | 70 | 81 | 125 | 9.5 | |

| 3.5 | 35 | 39 | 70 | 3.5 | 10 | 75 | 87 | 133 | 10 | |

| 4 | 38 | 43 | 75 | 4 | 10.2 | 75 | 87 | 133 | 10.2 | |

| 4.5 | 42 | 47 | 80 | 4.5 | 10.5 | 75 | 87 | 133 | 10.5 | |

| 5 | 46 | 52 | 80 | 5 | 10.8 | 81 | 94 | 142 | 10.8 | |

| 5.5 | 50 | 57 | 93 | 5.5 | 11 | 81 | 94 | 142 | 11 | |

| 6 | 50 | 57 | 93 | 6 | ]. | 81 | 94 | 142 | 11.5 | |

| 6.5 | 55 | 63 | 1 | 6.5 | 12 | 85 | 1 | 51 | 12 | |

| 7 | 60 | 69 | 107 | 7 | 13 | 85 | 101 | 51 | 13 | |

| 7.5 | 60 | 69 | 107 | 7.5 | 14 | 91 | 108 | 160 | 14 | |

| 8 | 65 | 75 | 117 | 8 | 15 | 96 | 114 | 163 | 15 | |

| 8.5 | 65 | 75 | 117 | 8.5 | 16 | 1 | 116 | 163 | 16 | |

| 9 | 70 | 81 | 125 | 9 |

Engineering Data

four-sided grinding

web thinning standard

30° RH helix

| d1 | d2 | d1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 4 | 39 | 43 | 82 | 6 | 10 | 74 | 87 | 130 | 10 | |

| 4.5 | 42 | 47 | 86 | 6 | 10.5 | 74 | 87 | 135 | 12 | |

| 5 | 46 | 52 | 91 | 6 | 11 | 80 | 94 | 42 | 12 | |

| 5.5 | 50 | 57 | 96 | 6 | 11.5 | 80 | 94 | 42 | 12 | |

| 6 | 50 | 57 | 96 | 6 | 12 | 85 | 1 | 49 | 12 | |

| 6.5 | 55 | 63 | 102 | 8 | 12.5 | 85 | 101 | 149 | 14 | |

| 7 | 60 | 69 | 108 | 8 | 13 | 85 | 1 | 149 | 14 | |

| 7.5 | 60 | 69 | 108 | 8 | 14 | 91 | 108 | 156 | 14 | |

| 8 | 65 | 75 | 114 | 8 | 15 | 96 | 114 | 163 | 16 | |

| 8.5 | 70 | 81 | 124 | 10 | 16 | 101 | 116 | 163 | 16 | |

| 9 | 70 | 81 | 124 | 10 | ||||||

| 9.5 | 70 | 81 | 124 | 10 |

Engineering Data

four-sided grinding

web thinning standard

30° RH helix

| dl | d2 | dl | d2 | |||||||

| (h7) | L3 | L2 | Ll | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 12 | 16 | 46 | 3 | 9 | 28 | 40 | 80 | 9 | |

| 3.5 | 15 | 20 | 52 | 3.5 | 9.5 | 28 | 40 | 80 | 9.5 | |

| 3.8 | 17 | 22 | 55 | 3.8 | 9 | 28 | 40 | 80 | 9.8 | |

| 4 | 17 | 22 | 55 | 4 | 10 | 31 | 43 | 80 | 10 | |

| 4.2 | 17 | 22 | 55 | 4.2 | 10.2 | 31 | 43 | 80 | 10.2 | |

| 4.5 | 18 | 24 | 58 | 4.5 | 10.5 | 31 | 43 | 80 | 0.5 | |

| 4.8 | 20 | 26 | 62 | 4.8 | 10.8 | 33 | 47 | 95 | 10.8 | |

| 5 | 20 | 26 | 62 | 5 | 11 | 33 | 47 | 95 | ll | |

| 5.5 | 21 | 28 | 66 | 5.5 | 11.5 | 33 | 47 | 95 | 1 | |

| 5.8 | 21 | 28 | 66 | 5.8 | 12 | 35 | 51 | 102 | 12 | |

| 6 | 21 | 28 | 66 | 6 | 2 | 35 | 51 | 102 | 2.5 | |

| 6.5 | 23 | 31 | 70 | 6.5 | 13 | 35 | 51 | 102 | 13 | |

| 6.8 | 25 | 34 | 74 | 6.8 | 14 | 37 | 54 | 7 | 14 | |

| 7 | 25 | 34 | 74 | 7 | 15 | 38 | 56 | 107 | 15 | |

| 7.5 | 25 | 34 | 74 | 7.5 | 16 | 38 | 58 | 107 | 6 | |

| 8 | 27 | 37 | 79 | 8 | 18 | 40 | 62 | 123 | 18 | |

| 8.5 | 27 | 37 | 79 | 8.5 | 20 | 42 | 66 | 131 | 20 |

Engineering Data

four-sided grinding

web thinning DIN 1412 form A

for machining of thread core holes

cutting till countersinking step

| d1 | d2 | d1 | d2 | |||||||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L3 | (h6) | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||||

| 2.5 | M3 | GS | 8.8 | 20 | 62 | 6 | 7.4 | M8 | GF | 21 | 47 | 80 | 10 | |

| 2.75 | M3 | GF | 8.8 | 20 | 62 | 6 | 8.5 | M10 | GS | 25.5 | 55 | 102 | 12 | |

| 33 | M4 | GS | 11.4 | 20 | 62 | 6 | 9.35 | M10 | GF | 25.5 | 55 | 102 | 12 | |

| 3.65 | M4 | GF | 11.4 | 20 | 62 | 6 | 10.2 | N12 | GS | 30 | 60 | 107 | 14 | |

| 4.2 | M5 | GS | 13.6 | 28 | 66 | 6 | 1.2 | M112 | GF | 30 | 60 | 107 | 14 | |

| 4.65 | M5 | GF | 13.6 | 28 | 66 | 6 | 12 | N14 | GS | 34.5 | 65 | 107 | 16 | |

| 5 | M6 | GS | 16.5 | 34 | 79 | 8 | 13.2 | N14 | GF | 34.5 | 65 | 107 | 16 | |

| 5.55 | M6 | GF | 16.5 | 34 | 79 | 8 | 14 | 16 | GS | 38.5 | 73 | 123 | 18 | |

| 6.8 | M8 | GS | 21 | 47 | 80 | 10 | 15.1 | l16 | GF | 38.5 | 73 | 123 | 18 |

Engineering Data

four-sided grinding

web thinning DIN 1412 form A

for machining of thread core holes

30° RH helix

| d1 | d2 | dl | d2 | |||||||||

| (h8) | L4 | L3 | L2 | L1 | (h6) | (h8) | L4 | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 2.5 | 34 | 8.8 | 39 | 70 | 3.4 | 8.5 | 80 | 25.5 | 94 | 42 | 11 | |

| 3.3 | 41 | 11.4 | 47 | 80 | 4.5 | 10.2 | 91 | 30 | 108 | 160 | 13.5 | |

| 4.2 | 50 | 13.6 | 57 | 93 | 5.5 | 12 | 101 | 34.F | 120 | 178 | 15.5 | |

| 5 | 55 | 16.5 | 63 | 101 | 6.6 | 14 | 109 | 38.5 | 130 | 191 | 17.5 | |

| 6.8 | 70 | 21 | 81 | 125 | 9 | 15.5 | 116 | 43.5 | 140 | 205 | 20 |