Want to Know More Imformations About Our Precision Cutting Tools?

Fill the form to let us know your need.

Our sales will get in touch with you.

According to the need to process different diameters of holes, and can achieve large holes in one-time processing, without the need to replace the drill bit and playing positioning holes and so on. On the forming workpiece of step parts, multiple step holes are processed by one-time forming drilling, composite forming, fast and time-saving. High efficiency, saving non-processing man-hours. Use special equipment to grind and process, high precision. Adopting high quality alloy bar, good wear resistance.

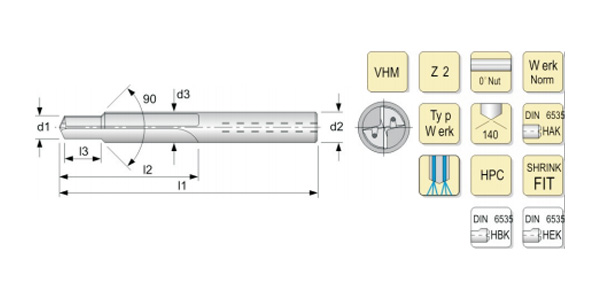

Solid Carbide Straight Flute Drill for Au. Cast iron

Engineering Data

four-sided grinding

straight flute

for machining of short chipping materials

for machining of thread core holes

cutting till countersinking step

| d1(h7 | L3 | L2 | L1 | d3 | d2 | d1(h7) | L3 | L2 | L1 | d3 | d2 | |||||

| mm | mm | mm | mm | mm | (h6) | mm | mm | mm | mm | mm | (h6) | |||||

| 3.3 | M4 | GS | 11.4 | 20 | 62 | 6 | 6 | 10.2 | M12 | GS | 30 | 60 | 107 | 14 | 14 | |

| 3.65 | M4 | GF | 11.4 | 20 | 62 | 6 | 6 | 11.2 | M12 | GF | 30 | 60 | 107 | 14 | 14 | |

| 4.2 | M6 | GS | 13.6 | 28 | 66 | 6 | 6 | 12 | M14 | GS | 34.5 | 65 | 115 | 16 | 16 | |

| 4.65 | M5 | GF | 13.6 | 28 | 66 | 6 | 6 | 13.2 | M14 | GF | 34.5 | 65 | 115 | 16 | 16 | |

| 5 | M6 | GS | 16.5 | 34 | 79 | 8 | 8 | 14 | M16 | GS | 38.5 | 73 | 123 | 18 | 18 | |

| 5.55 | M6 | GF | 16.5 | 34 | 79 | 8 | 8 | 15.1 | M16 | GF | 38.5 | 73 | 123 | 18 | 18 | |

| 6.8 | M8 | GS | 21 | 47 | 89 | 10 | 10 | 15.5 | M18 | GS | 43.5 | 79 | 131 | 20 | 20 | |

| 7.4 | M8 | GF | 21 | 47 | 89 | 10 | 10 | 16.9 | M18 | GF | 43.5 | 79 | 131 | 20 | 20 | |

| 8,5 | M10 | GS | 25.5 | 55 | 102 | 12 | 12 | 17.5 | M20 | GS | 47.5 | 89 | 147 | 22 | 20 | |

| 9.35 | M10 | GF | 25.5 | 55 | 102 | 12 | 12 | 18.9 | M20 | GF | 47.5 | 89 | 147 | 22 | 20 |

| ¢d1 (h7) mm | L3 mm | L2 mm | L1 mm | ¢d3 mm | ¢d2 (h6) mm | ||

| 3.3 | M4 | GS | 11.4 | 20 | 62 | 6 | 6 |

| 3.65 | M4 | GF | 11.4 | 20 | 62 | 6 | 6 |

| 4.2 | M5 | GS | 13.6 | 28 | 66 | 6 | 6 |

| 4.65 | M5 | GF | 13.6 | 28 | 66 | 6 | 6 |

| 5 | M6 | GS | 16.5 | 34 | 79 | 8 | 8 |

| 5.55 | M6 | GF | 16.5 | 34 | 79 | 8 | 8 |

| 6.8 | M8 | GS | 21 | 47 | 89 | 10 | 10 |

| 7.4 | M8 | GF | 21 | 47 | 89 | 10 | 10 |

| 8.5 | M10 | GS | 25.5 | 55 | 102 | 12 | 12 |

| ¢d1 (h7) mm | L3 mm | L2 mm | L1 mm | ¢d3 mm | ¢d2 (h6) mm | ||

| 10.2 | M12 | GS | 30 | 60 | 107 | 14 | 14 |

| 11.2 | M12 | GF | 30 | 60 | 107 | 14 | 14 |

| 12 | M14 | GS | 34.5 | 65 | 115 | 16 | 16 |

| 13.2 | M14 | GF | 34.5 | 65 | 115 | 16 | 16 |

| 14 | M16 | GS | 38.5 | 73 | 123 | 18 | 18 |

| 15.1 | M16 | GF | 38.5 | 73 | 123 | 18 | 18 |

| 15.5 | Ml8 | GS | 43.5 | 79 | 131 | 20 | 20 |

| 16.9 | M18 | GF | 43.5 | 79 | 131 | 20 | 20 |

| 17.5 | M20 | GS | 47.5 | 89 | 147 | 22 | 20 |

| 18.9 | M20 | GF | 47.5 | 89 | 147 | 22 | 20 |