The newly developed (Al, Cr, Si)N coating with oxidation resistance and lubricity at HRC 55 degrees or higher, combined with the (Al, Ti, Si)N coating with excellent wear resistance and adhesion, provides excellent wear resistance in machining of high hardness steels. Integral 4-flute type for various inclination angles enables large feeds for machining at various inclination angles. Highly efficient machining is possible by increasing the feed rate in finishing operations. Our solid carbide end mill cutter and metal milling tools, featuring advanced (Al, Cr, Si)N and (Al, Ti, Si)N coatings, deliver exceptional wear resistance and efficiency in machining high hardness steels, even at various inclination angles.

Staggered-teeth end mill with T-Slot

| Code | Blade Diameter D | Shank Diameter d | Blade length 1 | Total Length L | Blade count X |

| CTM41808M2 | 18 | 2# | 8 | 82 | 4 |

| CTM42109M2 | 21 | 2# | 9 | 100 | 4 |

| CTM62511M2 | 25 | 2# | 11 | 105 | 6 |

| CTM62912M2 | 29 | 2# | 12.5 | 105 | 6 |

| CTM63214M2 | 32 | 2# | 14 | 11 | 6 |

| CTM63615M3 | 36 | 3# | 15.5 | 130 | 6 |

| CTM64018M3 | 40 | 3# | 18 | 140 | 6 |

| CTM64520M3 | 45 | 3# | 20 | 140 | 6 |

| CTM65022M4 | 50 | 4# | 22 | 175 | 6 |

| CTM85724M4 | 57 | 4# | 24 | 180 | 8 |

| CTM86028M4 | 60 | 4# | 28 | 190 | 8 |

| CTM87235M5 | 72 | 5# | 35 | 230 | 8 |

| CTM88540M5 | 85 | 5# | 40 | 240 | 8 |

| CTM89544M5 | 95 | 5# | 44 | 250 | 8 |

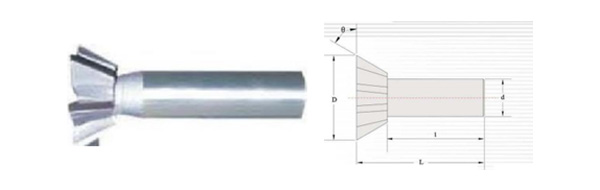

| Code | Blade Diameter D | Shank Diameter d | Blade length 1 | Total Length L | θ | Blade count X |

| CGM31604FA45 | 16 | 12 | 4 | 60 | 45° | 3 |

| CGM42005FA45 | 20 | 12 | 5 | 63 | 45° | 4 |

| CGM62506FA45 | 25 | 12 | 6.3 | 67 | 45° | 6 |

| CGM63208FA45 | 32 | 16 | 8 | 71 | 45° | 6 |

| CGM31606FA55 | 16 | 12 | 6.3 | 60 | 45° | 3 |

| CGM42008FA55 | 20 | 12 | 8 | 63 | 45° | 4 |

| CGM62510FA55 | 25 | 12 | 10 | 67 | 45° | 6 |

| CGM63212FA55 | 32 | 16 | 12.5 | 71 | 45° | 6 |

| CGM31606FA60 | 16 | 12 | 6.3 | 60 | 45° | 3 |

| CGM42008FA60 | 20 | 12 | 8 | 63 | 45° | 4 |

| CGM62510FA60 | 25 | 12 | 10 | 67 | 45° | 6 |

| CGM63212FA60 | 32 | 16 | 12.5 | 71 | 45° | 6 |

| CGM64015FA60 | 40 | 20 | 15 | 85 | 45° | 6 |

| CGM64520FA60 | 45 | 20 | 20 | 90 | 45° | 6 |

| CGM65020FA60 | 50 | 20 | 25 | 95 | 45° | 6 |

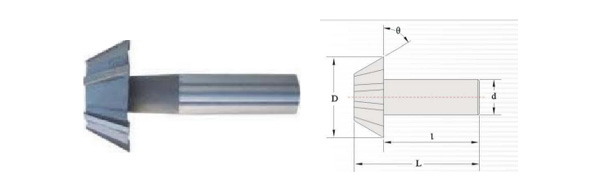

| Code | Blade Diameter D | Shank Diameter d | Blade length 1 | Total Length L | Blade count X | θ |

| □-CWM31604FA60 | 16 | 12 | 4 | 60 | 3 | 45° |

| □-CWM42005FA60 | 20 | 12 | 5 | 63 | 4 | 45° |

| □-CWM62506FA60 | 25 | 12 | 6.3 | 67 | 6 | 45° |

| □-CWM63208FA60 | 32 | 16 | 8 | 71 | 6 | 45° |

| □-CWM31606FA55 | 16 | 12 | 6.3 | 60 | 3 | 55° |

| □-CWM42008FA55 | 20 | 12 | 8 | 63 | 4 | 55° |

| □-CWM62510FA55 | 25 | 12 | 10 | 67 | 6 | 55° |

| □-CWM63212FA55 | 32 | 16 | 12.5 | 71 | 6 | 55° |

| □-CWM31606FA60 | 16 | 12 | 6.3 | 60 | 3 | 60° |

| □-CWM42008FA60 | 20 | 12 | 8 | 63 | 4 | 60° |

| □-CWM62510FA60 | 25 | 12 | 10 | 67 | 6 | 60° |

| □-CWM63212FA60 | 32 | 16 | 12.5 | 71 | 6 | 60° |

| □-CWM64015FA60 | 40 | 20 | 15 | 85 | 6 | 60° |

| □-CWM66020FA60 | 45 | 20 | 20 | 90 | 6 | 60° |

| □-CWM65020FA6O | 50 | 20 | 25 | 95 | 6 | 60° |